When you’re hauling heavy, sticky, or abrasive materials every day, the last thing you want to deal with is the wrong truck bed liner. Whether you’re in mining, construction, agriculture, or roadworks, using the wrong liner doesn’t just slow down your operation; it puts your equipment and crew at risk.

So, what happens when your liner isn’t fit for purpose? And why is using the right truck bed liner important? Here’s what you need to know.

Premature Wear and Tear

Not all liners are designed to handle the same level of usage. Some liners are meant for cosmetic protection or light-duty use, not industrial-grade conditions.

If you’re working with high-friction or high-impact loads, using an underperforming liner can lead to accelerated wear. For example, some spray-in liners, often chosen for their low upfront cost or convenience, have been known to wear out after just one load of abrasive material. They’re not engineered to handle continuous exposure to sharp, heavy, or high-friction loads like gravel, ore, or concrete spoil.

The result? You end up paying for frequent reapplications, liner repairs, or even structural damage to your truck bed, all of which eat into your operating budget and uptime.

Unreliable Unloading and Material Hang-Up

Another major issue with the wrong type of liner is a persistent material hang-up. This occurs when the material fails to slide out cleanly, clinging to specific sections of the tray, even if you’re fully tipped.

Liners with high surface energy (like exposed steel or subpar plastic coatings) create friction and adhesion that prevent free flow, especially with sticky materials such as clay, compost, or recycled asphalt. Even with certain spray-in liners, some areas may still cause the load to cling, requiring extra labour, additional tipping cycles, or even manual clearing to complete unloading.

This doesn’t just slow things down. It also increases fuel use, causes unnecessary stress on the hoist, and puts operators at risk when manually addressing material stuck inside the body.

Tipping Angle Complications and Roll Risks

Liners that don’t reduce friction and adhesion effectively also tend to increase the tipping angle required to unload. In some cases, trucks need to be raised to dangerously steep angles before the load fully discharges. This higher tipping angle increases the risk of rollovers, particularly when the ground is uneven or when the load suddenly breaks free all at once.

Material behaviour can also vary with changing weather and temperature conditions. A load that slides out easily on a dry day may stick stubbornly when moisture, humidity, or freezing temperatures come into play. With the wrong liner, these effects are amplified. Poor surface properties force operators to raise tipping angles further than expected, increasing the risk of sudden load shifts and rollovers.

Impact on Maintenance and Fleet Life

The wrong liner impacts performance and equipment longevity. If materials consistently hang up, wear down the liner, or force your hoists, tipping frame, and chassis to operate beyond safe angles, you’ll start to see more frequent maintenance issues.

Body repairs, welding patches, or hoist replacements are far more expensive than installing a high-performing liner. Over time, the wrong liner reduces fleet life, increases costs, and causes more downtime.

Variability with Different Load Types

Not every liner handles different materials with equal performance. A liner that seems fine with dry grain might struggle with wet sand or recycled road base. If your fleet handles varied loads throughout the week, consistency matters.

Inferior liners tend to perform well with some materials but completely fail with others. That unpredictability is a huge issue for operators who need reliable, repeatable results, especially when timelines are tight or projects are high-stakes.

You Can’t Afford to Guess When It Comes To Truck Bed Liners

Liner selection should never be a guessing game. A liner that wears quickly, performs inconsistently, or creates operational hazards will cost more in the long run than one that’s built to handle your specific use case.

Whether your trucks operate in mining pits, construction sites, or agricultural fields, your liner should offer:

- Long-lasting wear resistance

- Low-friction material discharge

- Improved unloading safety

- Reduced equipment strain

- Reliable performance across multiple load types

If your current liner is causing more problems than it’s solving, it might be time to explore a better alternative.

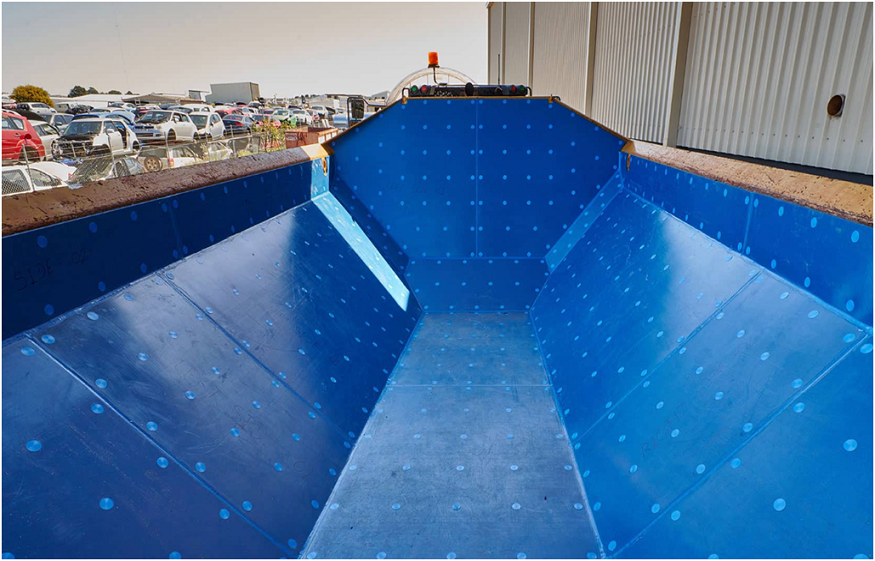

One proven solution is switching to a UHMWPE-based liner designed specifically for industrial haulage. With its low-friction surface, high wear resistance, and consistent performance across varied loads and weather conditions, a UHMWPE-based liner helps eliminate material hang-up, reduces tipping angles, and protects your equipment for the long haul.

Don’t let the wrong liner hold your fleet back. Choose the one that keeps your operation running safer, cleaner, and more cost-effectively.